【印刷可能】 s&op process cycle 963153

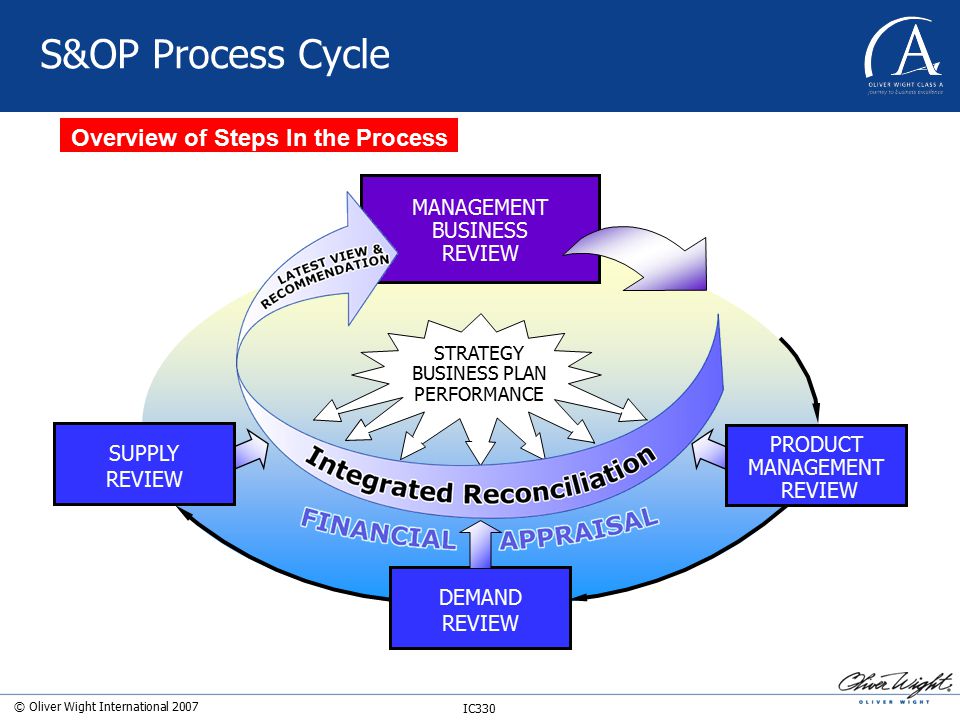

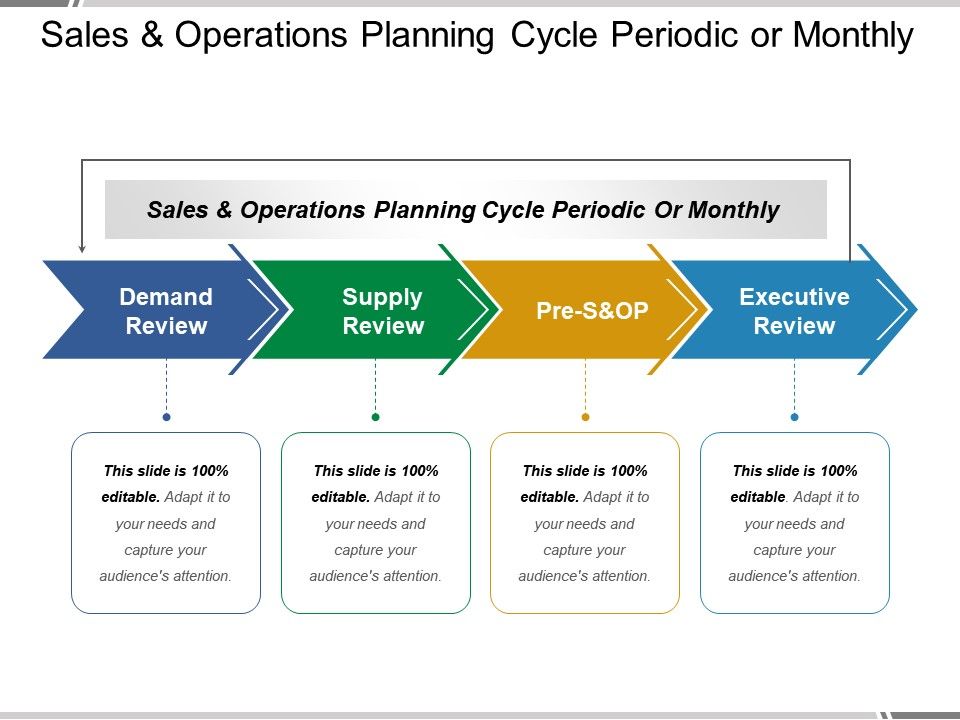

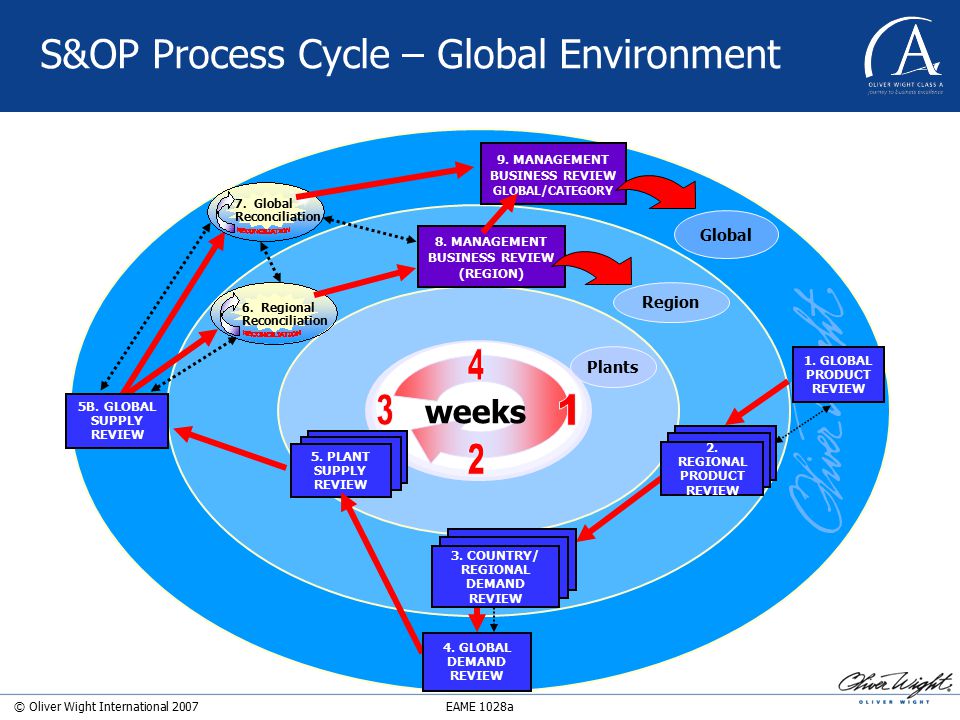

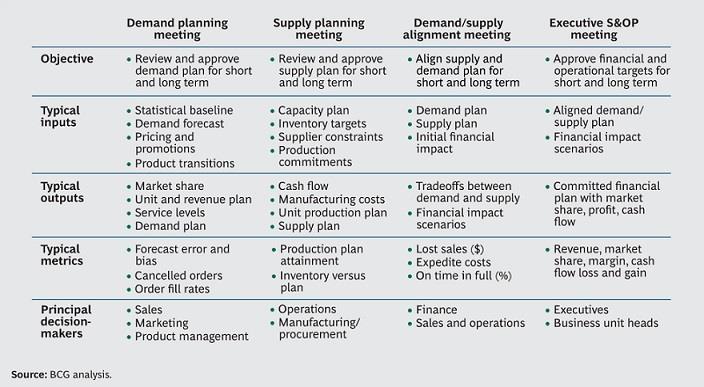

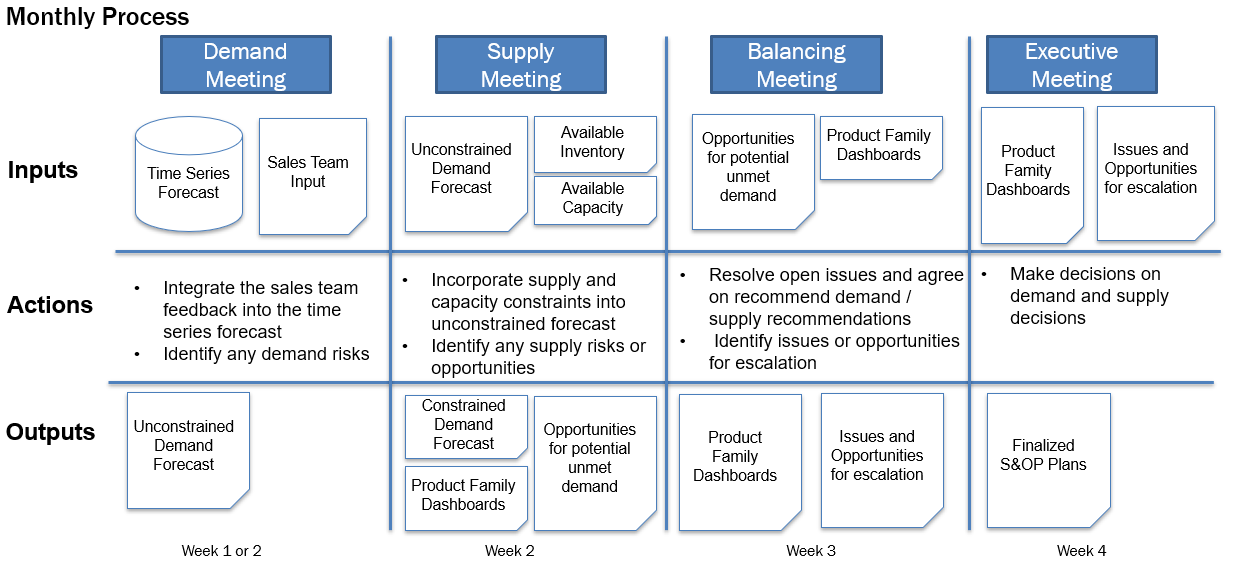

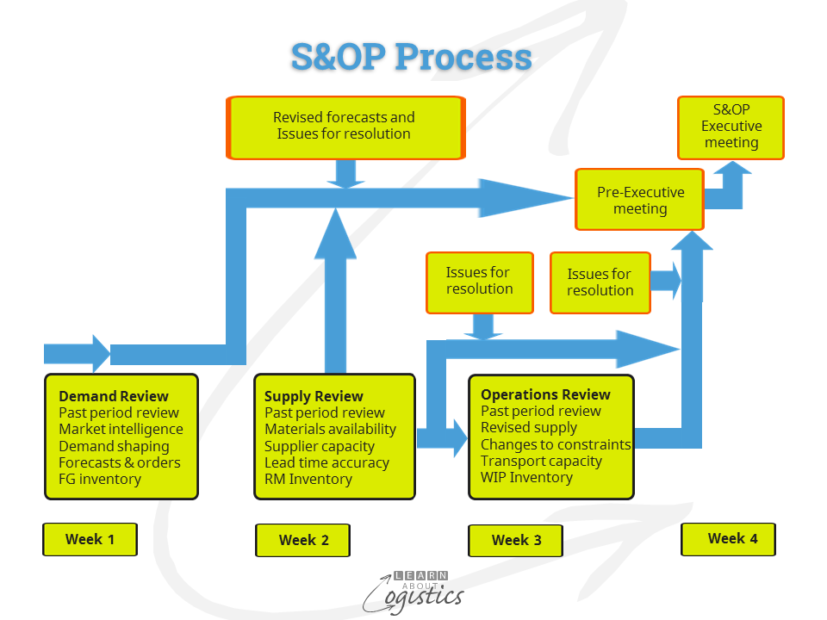

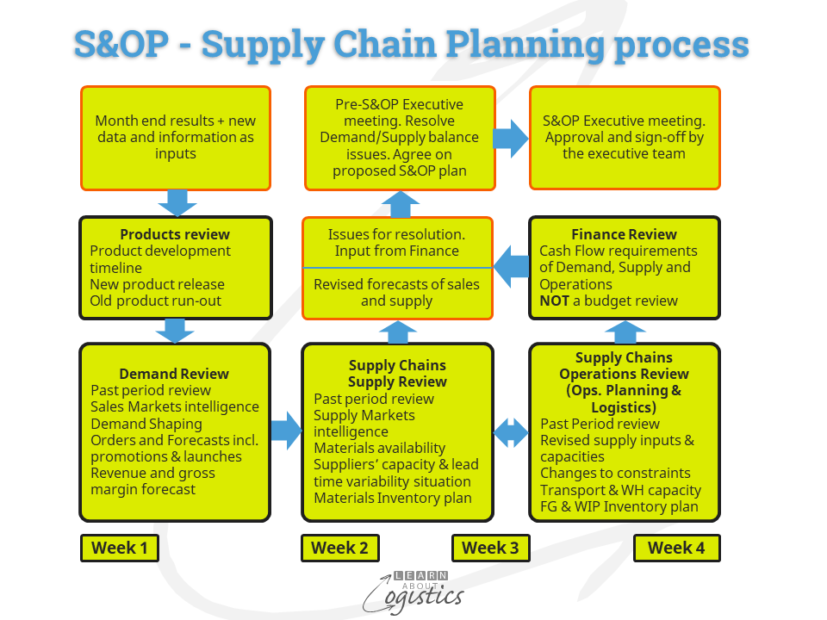

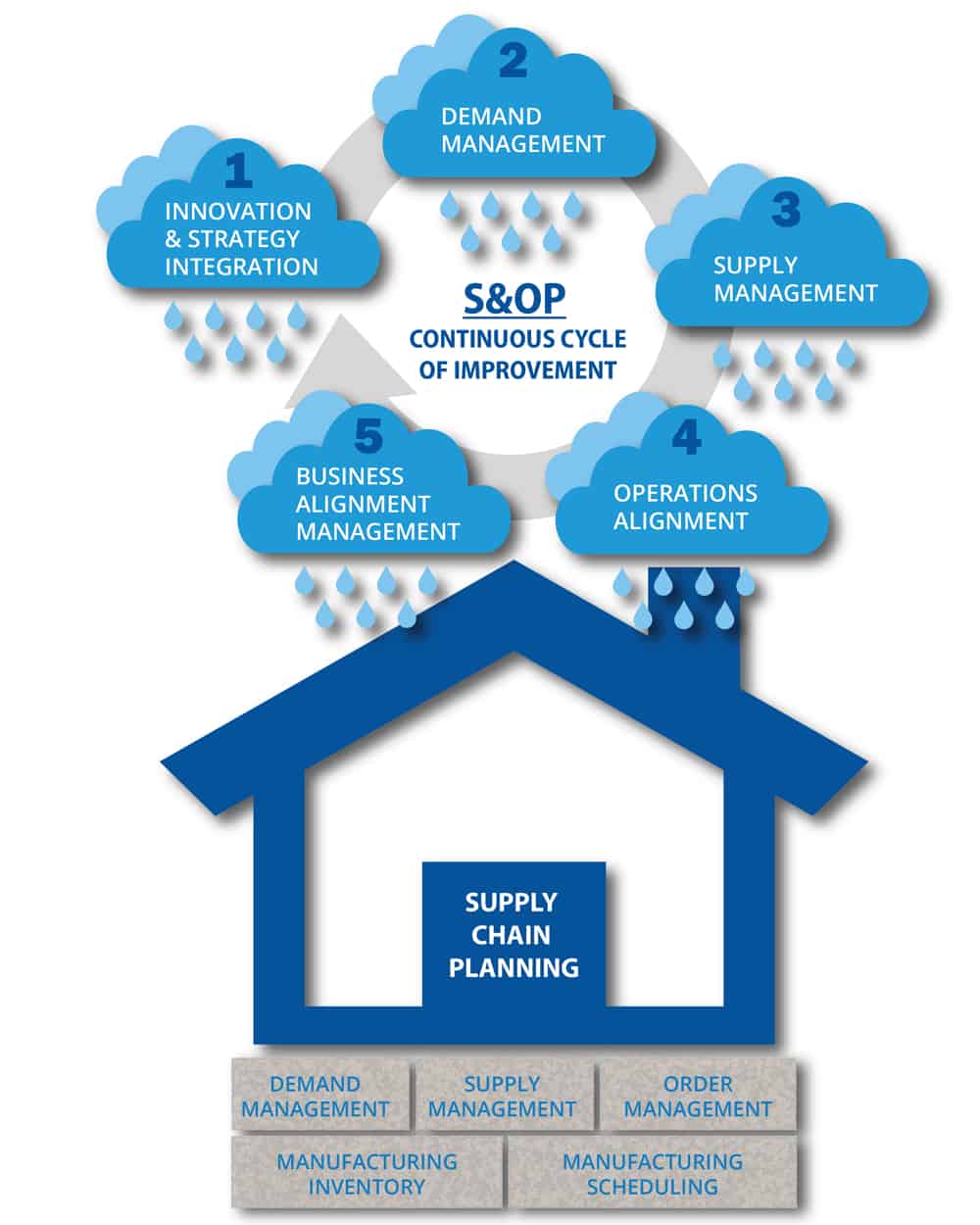

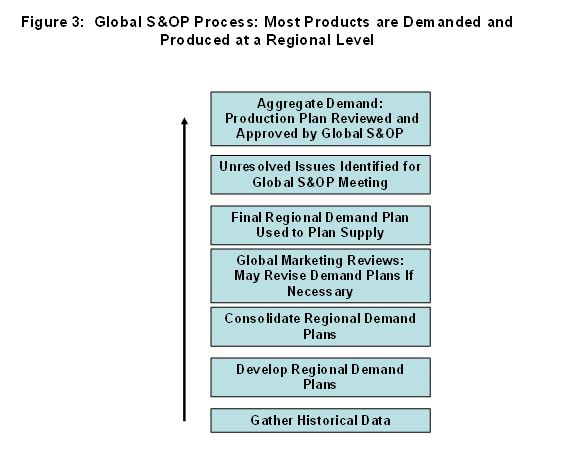

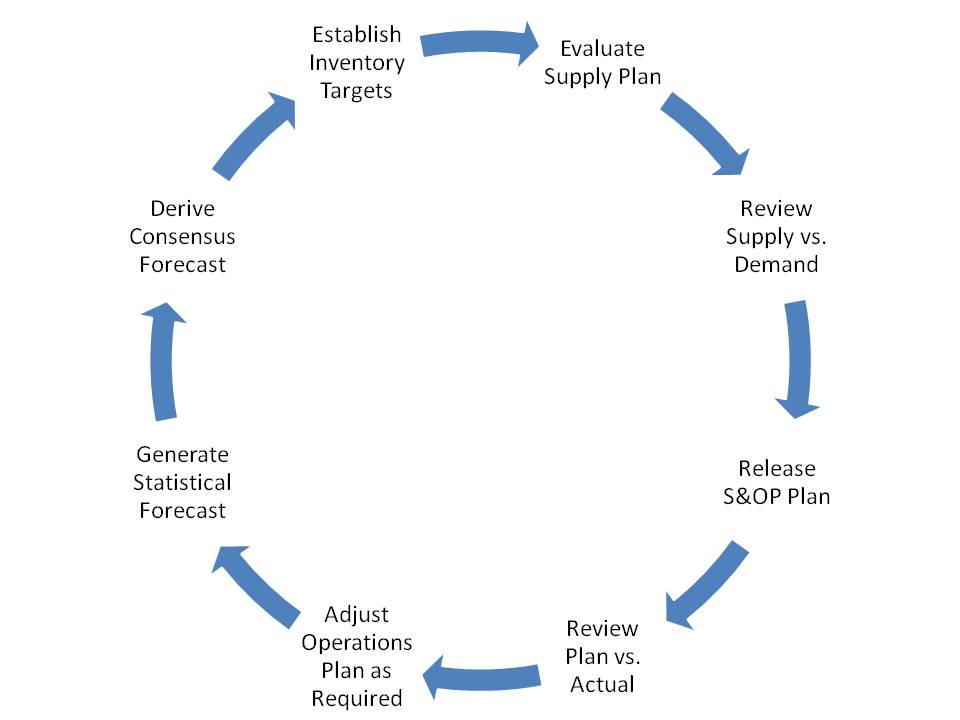

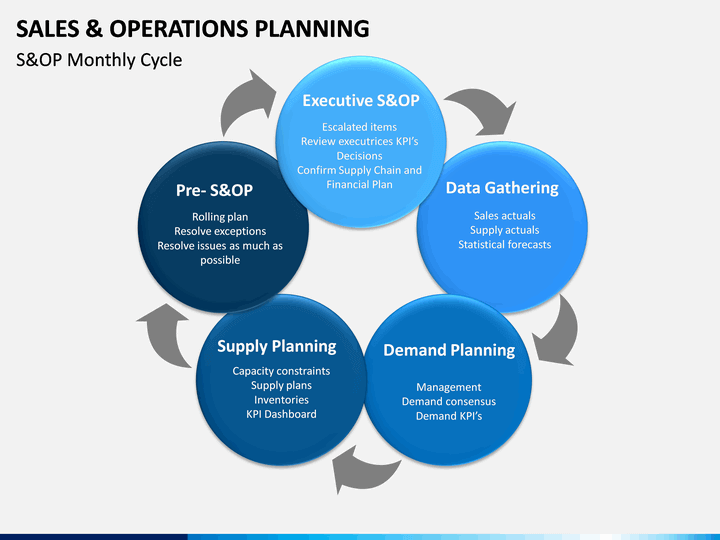

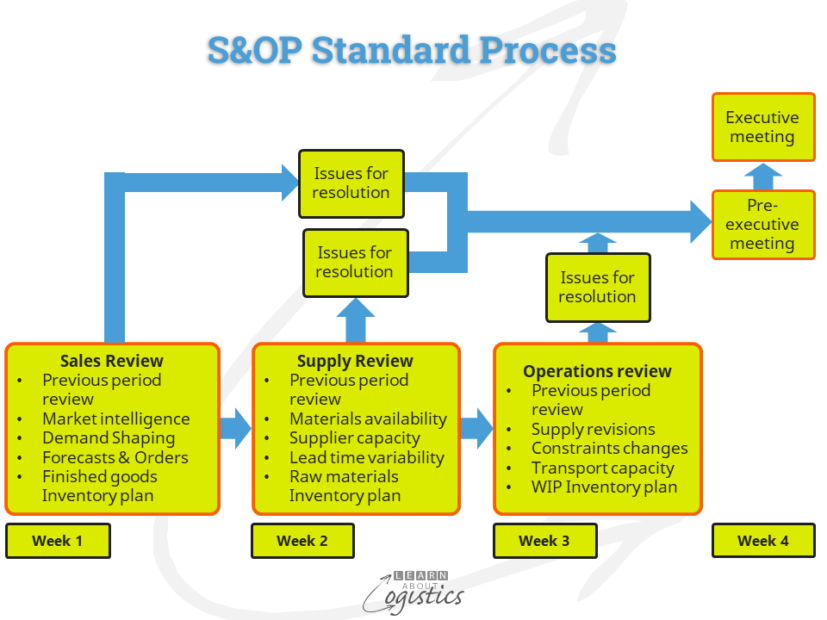

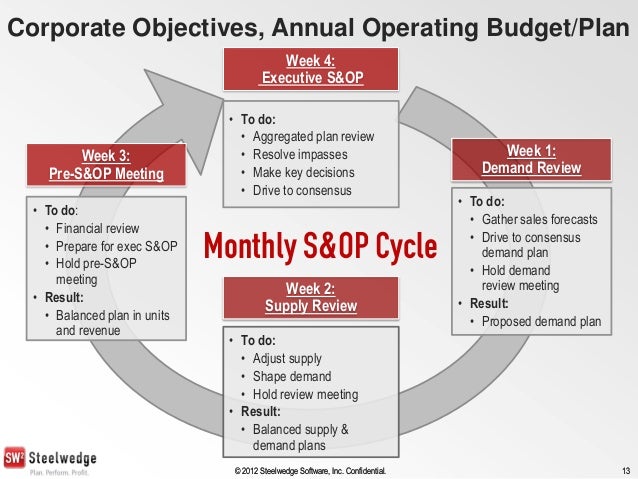

A poorly implemented S&OP process can trigger a vicious cycle in which existing failings in the process are exacerbated over time, leading to a further deterioration of key S&OP performance indicators Unfortunately, S&OP has often failed to live up to its promise According to research, around 5070 percent of businesses have been struggling to reap its full benefit EXHIBIT 1 FourSales and Operations Planning (S&OP) Definition ‐ A process to develop tactical plans that provide management the ability to strategically direct its businesses to achieve competitive advantage on a continuous basis by integrating customerfocused marketing plans for new and existing products with the management of the supply chain The process brings together all the plans for the Planning cycle A standard frequency To facilitate comparisons, a client organisation adopted a common four week planning period, with 13 planning periods in a year;

Software For Sales Operations Planning In Europe Supply Chain Movement

S&op process cycle

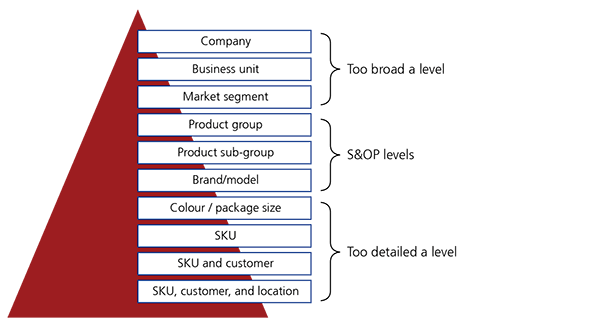

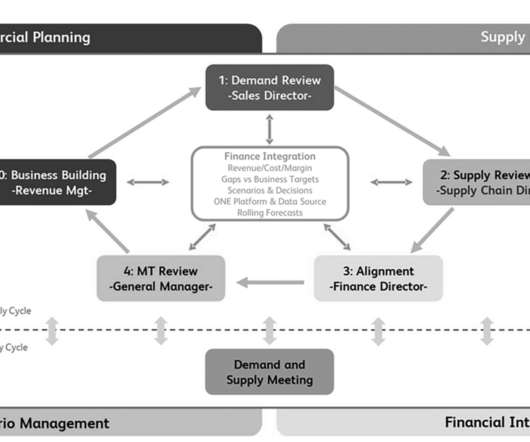

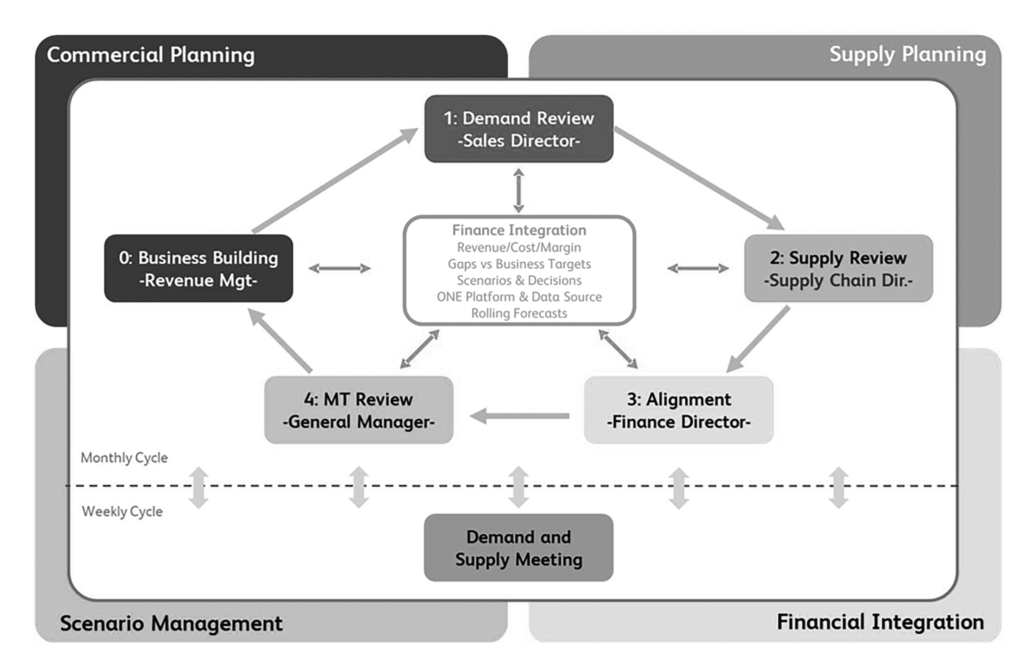

S&op process cycle-Reporting structure Each S&OP process is chaired by its P&L responsible manager; The first step for the supply chain planning leader is to identify the S&OE content in the S&OP process and move it to a separate agenda As a rule of thumb, anything that covers the nearterm horizon, commonly 0 to 3 months, is S&OE It deals with all the issues stemming from actual demand and supply — the reality of supply chain that is

S Op Process

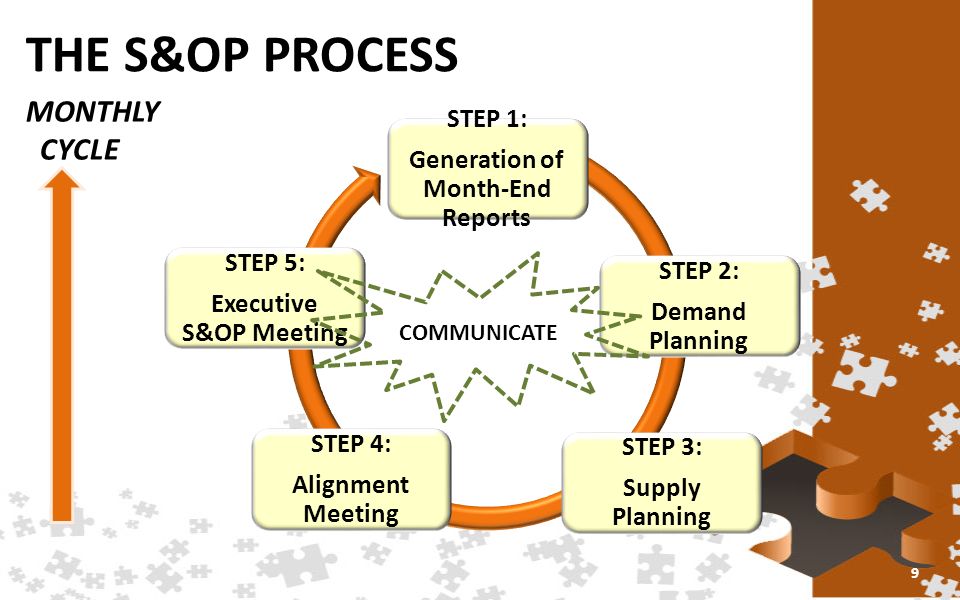

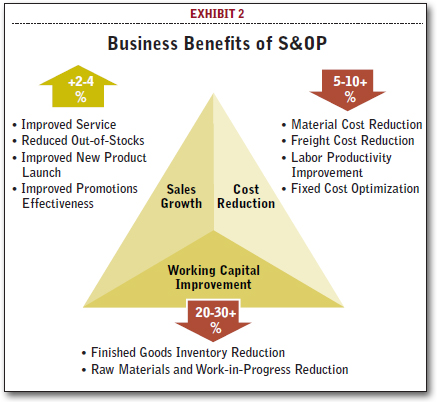

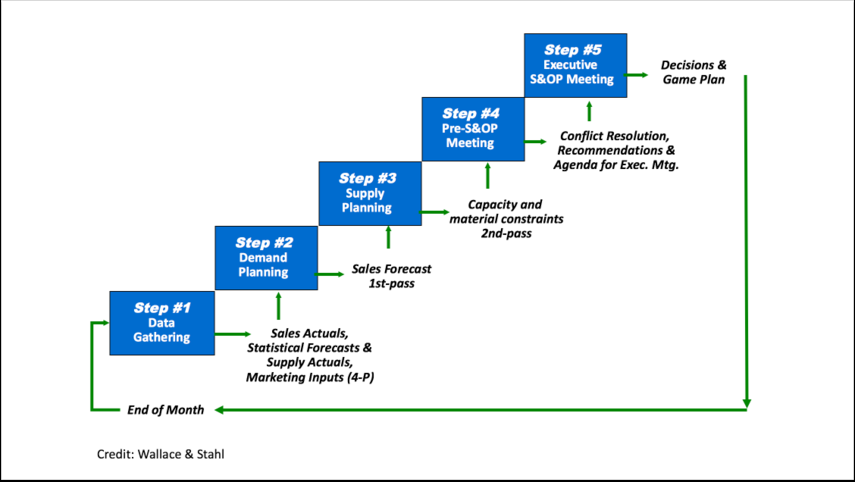

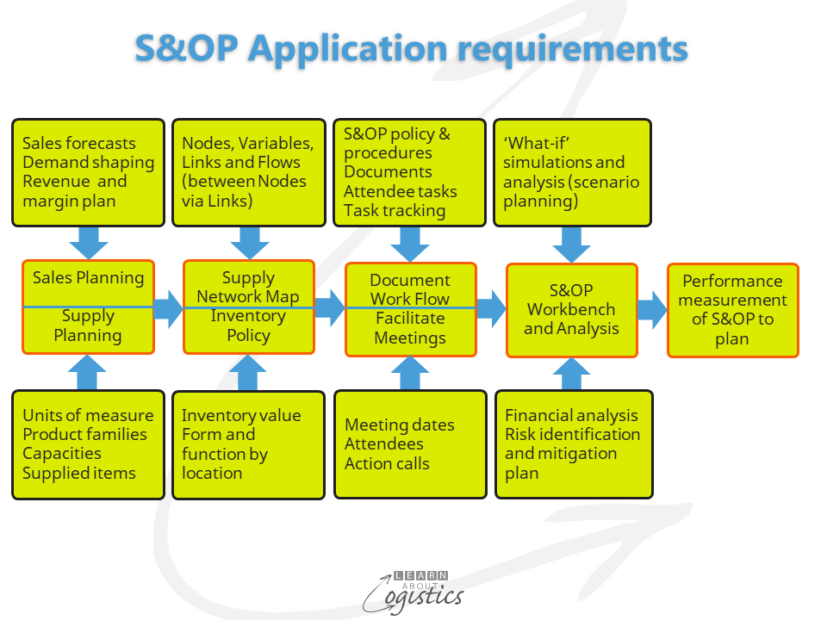

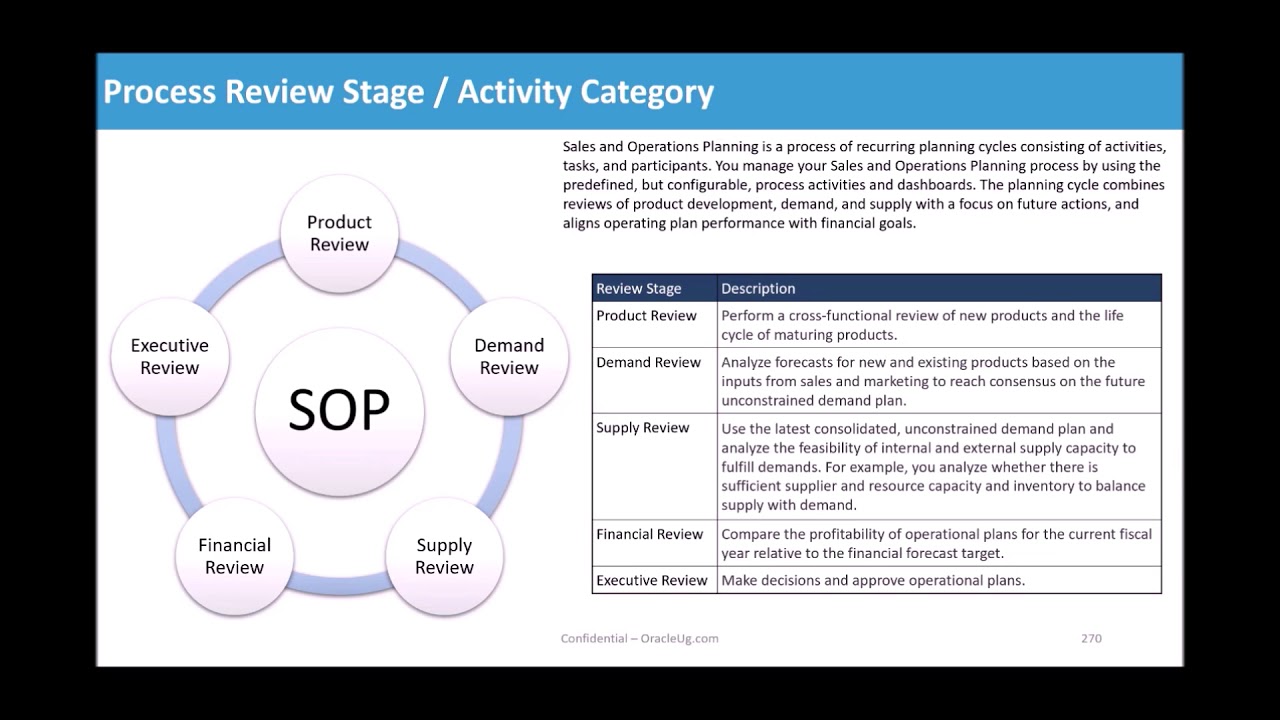

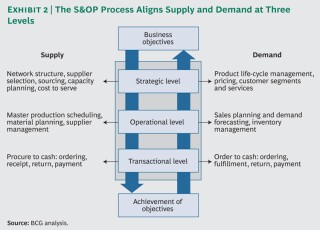

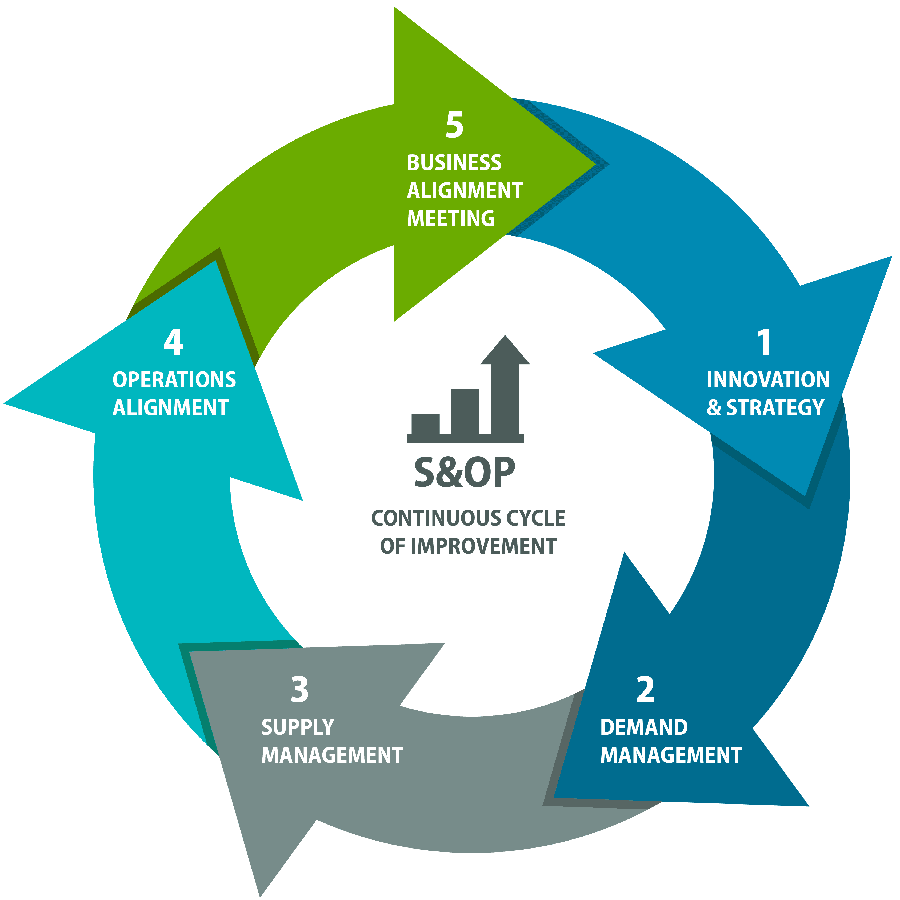

S&OP gives management the ability to direct its business to achieve a sustainable competitive advantage The overall objective of S&OP is to arrive at a business "Game Plan" to help manage and allocate critical resources to meet the needs of the customer at the lowest cost S&OP is a fivestep process as illustrated in Figure 135% shorter cashtocash cycle times;Supply Network flows Mapping the nodes and links of the Network Illustrate the interrelationships of

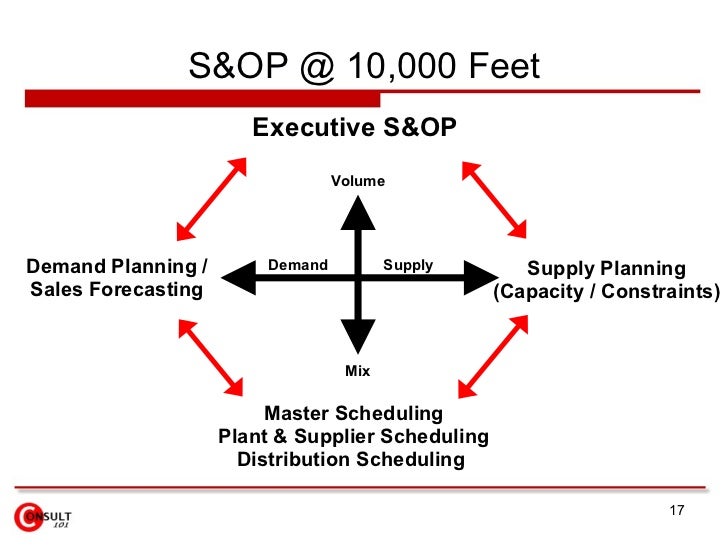

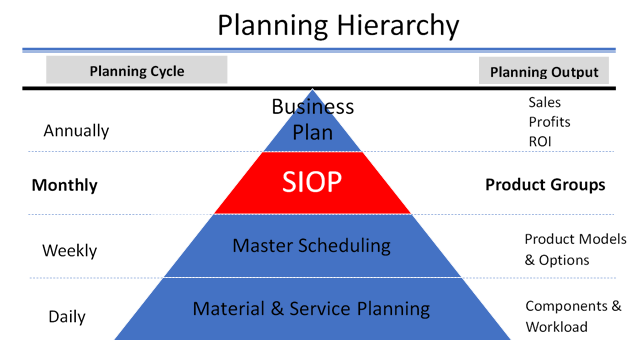

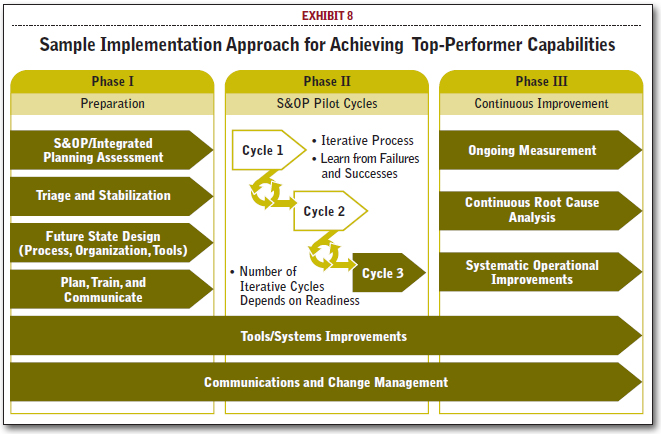

There are two distinct phases to S&OP 1) process design, and 2) process conduct In the design phase, all of the technical workings are engineered, and in the conduct phase S&OP is used as a business management process The following 10 steps describe how to go about these two phases Steps 15 are design and steps 610 are conduct 1 Decide to do it This seems quite obvious,The most important S&OP vital sign is whether the executive leader is directly involved in the process by participating and providing leadership in each executive S&OP meeting In this context, the executive leader is the head of the organization in the position of CEO, president, managing director, general manager, or P&L owner S&OP is successful because it aligns planning across S&OP Process – what, where, when, which, who, why etc Annually Monthly Weekly Daily Sales Profits ROI Product Groups Product Models & Options Components & workload Planning Cycle Planning Output S&OP 16 S&OP @ 100,000 Feet Executive S&OP A process to reconcile, agree upon, and communicate the company game plan Product Development (New Product

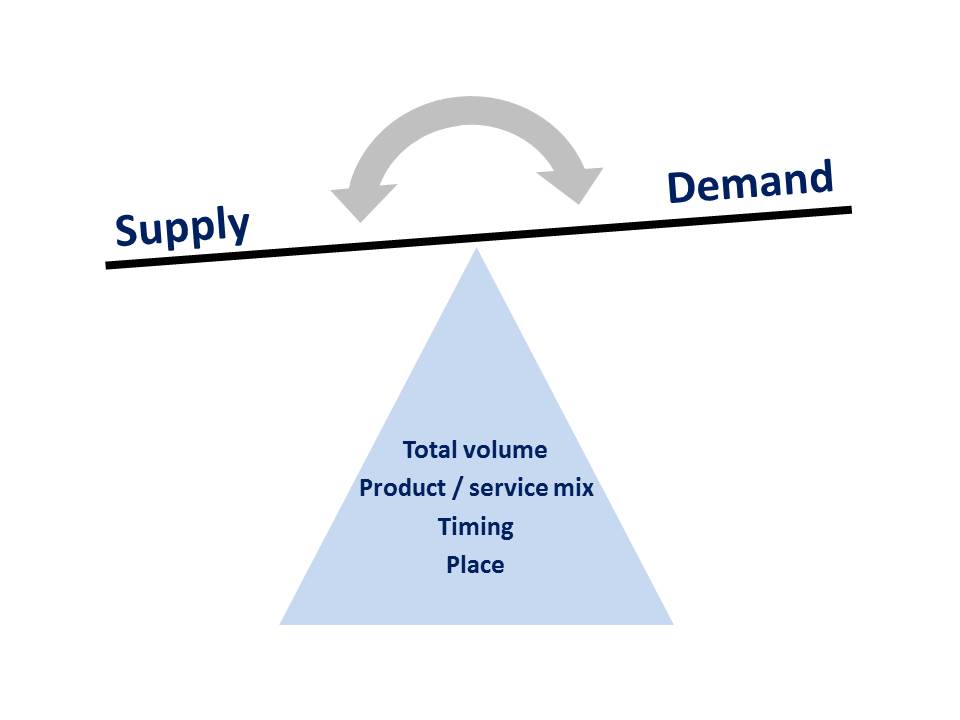

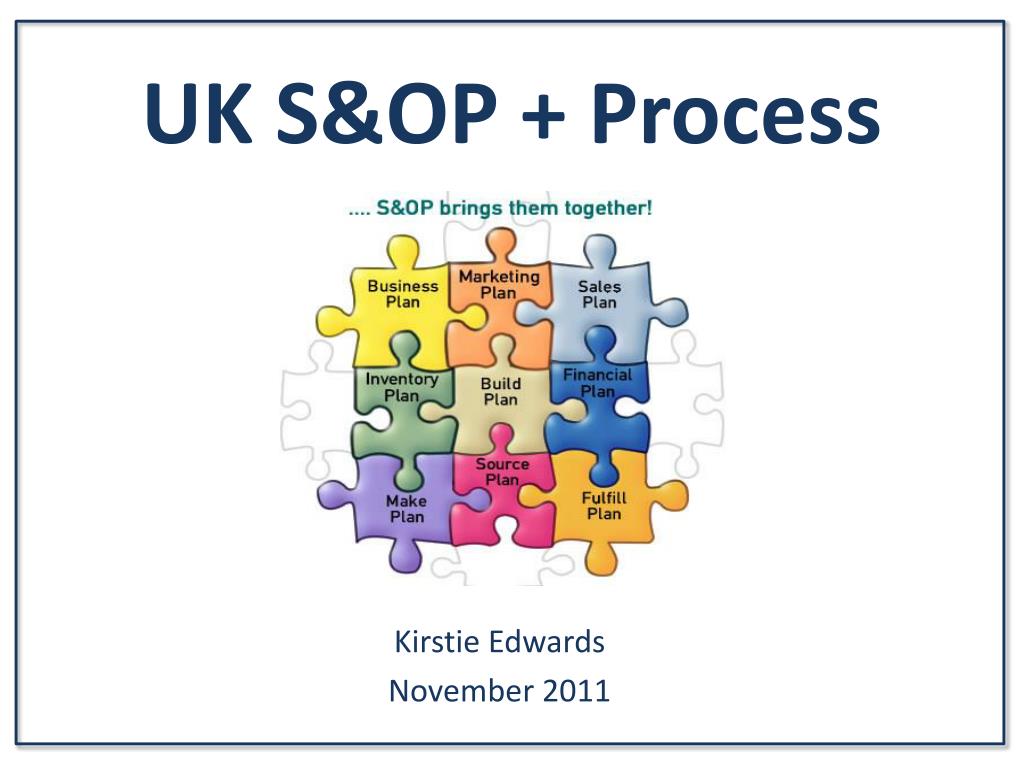

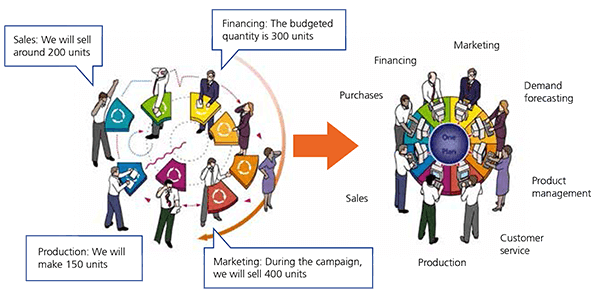

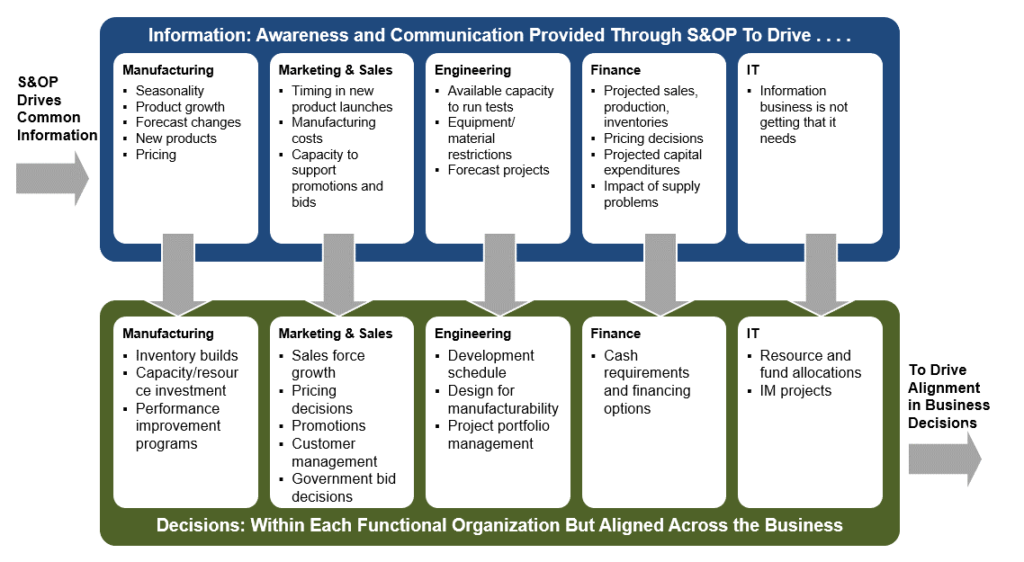

In this article, we define a typical S&OP process and will explain how to implement the process According to IBF, S&OP is a process that coordinates different areas of the business to meet customer demand with the appropriate level of supply When establishing your process, it is important to consider who will be responsible for each step of the process You will also want to Set Up Sales and Operations Execution Process to Support the S&OP Cycle Published 28 January 16 ID G Analyst(s) Marko Pukkila Summary S&OE is an oftenoverlooked process that keeps manufacturers' S&OP from reaching its full potential This research introduces the S&OE concept to supply chain planning leaders and offers first steps in Sales and operations planning (S&OP) is a popular process that aligns a company's diverse functions while balancing supply and demand S&OP gives executives a comprehensive overview of the business so they can grasp where it stands (in all its complexity) This allows them to continuously match highlevel strategy with daytoday operational tactics in all departments

S Op Process

Example Of The Monthly S Op Calendar Of The Company Studied Source Download Scientific Diagram

Process A robust S&OP process description which is deployed with discipline and consistency Systems Providing effective and wellintegrated systems to facilitate execution of a regular monthly planning cycle People Building capability across the enterprise functions and creating the organizational structures and teams to leverage this capability Mindsets &The S&OP process, which typically happens monthly, aligns operational areas – such as sales, marketing, product development, manufacturing, procurement, finance, and accounting – so they work in concert to meet financial and organizational goals The sales and operations planning process delivers an updated, rolling operational plan and demand plan that typically extends 18 S&OE smooths the daytoday volatility for more controlled operations In Set Up Sales and Operations Execution Process to Support the S&OP Cycle Pukkila explains, "Because of the shortterm view to the supply chain and manufacturing management, the daytoday noise and volatility seem worse than it may be The result in many companies in this situation is that they

Going Global With Sales And Operations Planning Ppt Video Online Download

Sales And Operations Planning Cycle Periodic Or Monthly Powerpoint Presentation Sample Example Of Ppt Presentation Presentation Background

S&OP Implementation Roadmap 1 S&OP Implementation Roadmap Implement S&OP, as a critical business process, championed by a crossfunctional team ofS&OP is largely a companywide, collaborative process performed on a recurring basis with participants from finance, operations, marketing, sales, and other groups as required In addition to the challenge of coordination and communication across this diverse group during the planning cycle, the primary challenges of sales and operations planning are Goal of S&OP process The primary goal of the sales and operations planning process is to facilitate the flow of information between demand and supply planning Master planning is concerned with coordinating the supply side of the organization It seeks efficient and economical ways to fulfill market demands by creating purchasing, manufacturing, and distribution plans The process

The S Op Cycle With Different Meetings đorđevic 17 P 44 Download Scientific Diagram

Sales And Operations Planning Myths Part 2 Supply Chain 24 7

1/10 th tenth of the stockouts;How It Works Sales and operations planning is typically led by senior management and is most often executed monthly It is an iterative process in which results from one planning cycle are compared with the next to provide management with trend information from across the business Participants evaluate timephased

S Op Process

Who Should Own Sales And Operations Planning I Kinaxis

Going Global With Sales And Operations Planning Ppt Video Online Download

Sales And Operations Planning Relex Solutions

The Long Game Vs The Short Integrating S Oe And S Op

Sales And Operations Planning Powerpoint Presentation Slides Presentation Powerpoint Templates Ppt Slide Templates Presentation Slides Design Idea

Make Super Session Wednesday May 29 Ppt Video Online Download

Solution Framework Of S Op In The Supply Chain Download Scientific Diagram

Achieve Excellence In Sales And Operations Planning Sapinsider

Sales And Operations Planning Relex Solutions

S Op The Evolving Supply Chain Lifeline Supplychainomics

Sales Inventory Operations Planning Si Op A Roadmap To Si Op Success Pragmatek Consulting

S Op And S Oe A Symbiotic Relationship

Software For Sales Operations Planning In Europe Supply Chain Movement

Continuous Sales And Operations Planning

Sales Operational Planning S Op Versus Integrated Business Planning Ibp Supply Chain Link Blog Arkieva

What Is S Op How S Op Works Demand Planning Com

Tackling Life S Big Questions What Is S Op

Sales Operations Planning Consulting Supply Velocity

Sap Integrated Business Planning Ibp Sales And Operations Planning 18 Sap Blogs

One Sales And Operations Planning Process Guide Cycle Powerpoint Slides Powerpoint Presentation Slides Ppt Slides Graphics Sample Ppt Files Template Slide

2

Smoother Execution Through S Op Supply Chain Management Review

Top Performer Benefits Of Effective Sales Operations Planning Supply Chain 24 7

Implement The S Op Process For Supply Chain Success Learn About Logistics

Is Your Business Suffering From S Op Churn Optimity Anz

Sales And Operations Planning S Op Logistiikan Maailma

Aktuelles Von Aca Solutions Sales And Operations Planning To Industrialize The Aerospace Supply Chain

What Is S Op Sales And Operations Planning Explained Anaplan

S Op Is The Hub Of Supply Chains In Your Business Learn About Logistics

S Op Planning Services Chainsequence Inc

Achieve Excellence In Sales And Operations Planning Sapinsider

Sales Operations Planning S Op Demand Planning Cargo

The 5 Most Common Sales Operations Planning Mistakes And How To Avoid Them Supply Chain 24 7

Sales And Operations Planning Report Do You Get Surprises

Sales And Operations Planning Business Forecasting Taruna Nagpal

Is Sales And Operations Planning A Digital Age Process Enterra Solutions

Achieve Excellence In Sales And Operations Planning Sapinsider

What Is S Op How S Op Works Demand Planning Com

Applications Requirements That Assist S Op Decisions Learn About Logistics

Events And S Op Supply Chain Brief

1

S Op Process Impacts Excess Finished Goods And Operational Efficiency Hawkeyeconsultingadvisors

What Is S Op How S Op Works Demand Planning Com

Getting To Grips With Sales And Operational Planning Bloor Research

Supply Chain Graphic Of The Week The S Op Process

Oracle Cloud Applications Supply Chain Planning Intro To Sales And Operations Planning Youtube

Pdf Sales And Operations Planning S Op An Overview

Integrating The S Op Process Go With The Flow Business 2 Community

Sales And Operations Planning

A Comprehensive Overview Of Sales And Operations Planning S Op

Ppt Uk S Op Process Powerpoint Presentation Free Download Id

Scm Portal Insight S Op S Oe The Key To Driving Supply Chain Agility

Sales And Operations Planning Powerpoint Template Sketchbubble

What Is S Op How S Op Works Demand Planning Com

S Op Five Steps To Get Started Supply Chain Shaman

2

What Are The Basic Elements Of The S Op Process Quora

What Is One Plan S Op Arkieva

Sales And Operations Planning Cycle Chainsequence Inc

S Op In Las Vegas Let S Learn Laugh And Be Entertained At The S Op Innovation Summit

Oracle Demantra Sales And Operations Planning User Guide

Sales And Operations Planning Relex Solutions

Sap Integrated Business Planning Ibp Sales And Operations Planning 18 Sap Blogs

What Is S Op Sales And Operations Planning Sap Insights

What Are The Basic Elements Of The S Op Process Quora

1

1

Top Performer Benefits Of Effective Sales Operations Planning Supply Chain 24 7

2

Sales And Operations Planning S Op 101 Smartsheet

Pdf Sales And Operations Planning A Comparison Between The Demand Driven And Traditional Approaches

2

Sales And Operations Planning Process Self Assessment

S Op Five Steps To Get Started Supply Chain Shaman

Sap Integrated Business Planning Ibp Sales And Operations Planning 18 Sap Blogs

Achieve Excellence In Sales And Operations Planning Sapinsider

Is S Op Excellence Slip Slidin Away Supply Chain Shaman

Achieve Excellence In Sales And Operations Planning Sapinsider

Monthly S Op Process Sales And Operations Planning Wikipedia Sales And Operations Planning Best Apps For Teachers Apps For Teachers

Sales Operations Planning Scpi

2

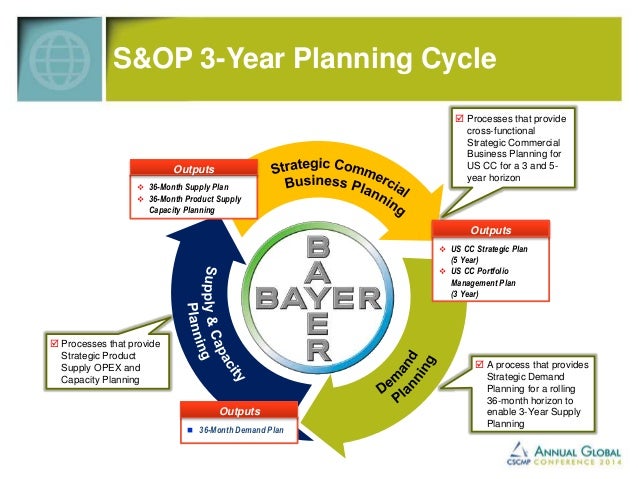

Cscmp 14 Bayer Putting The S Back In S Op

Proactively And Reactively Managing Risks Through Sales Amp Operations Planning Emerald Insight

A Comprehensive Overview Of Sales And Operations Planning S Op

Scielo Brasil Avaliacao Da Maturidade Do Processo De S Amp Op Em Uma Empresa De Material De Escrita Um Estudo De Caso Avaliacao Da Maturidade Do Processo De S Amp Op Em Uma Empresa

How S Op Improves Your Organization Tmc Fr

Exploring The Many Applications Of Aimms In Supply Chain Planning

A Common S Op Process For Your Business Helps Planning Learn About Logistics

1

Proactively And Reactively Managing Risks Through Sales Amp Operations Planning Emerald Insight

Supply Review Meetings

Sales And Operations Planning S Op Logistiikan Maailma

S Op Five Steps To Get Started Supply Chain Shaman

Improving Profitability With Sales Operations Planning Magellan Consulting Group

Implementing A Sales Operations Planning S Op Process Plex Demandcaster

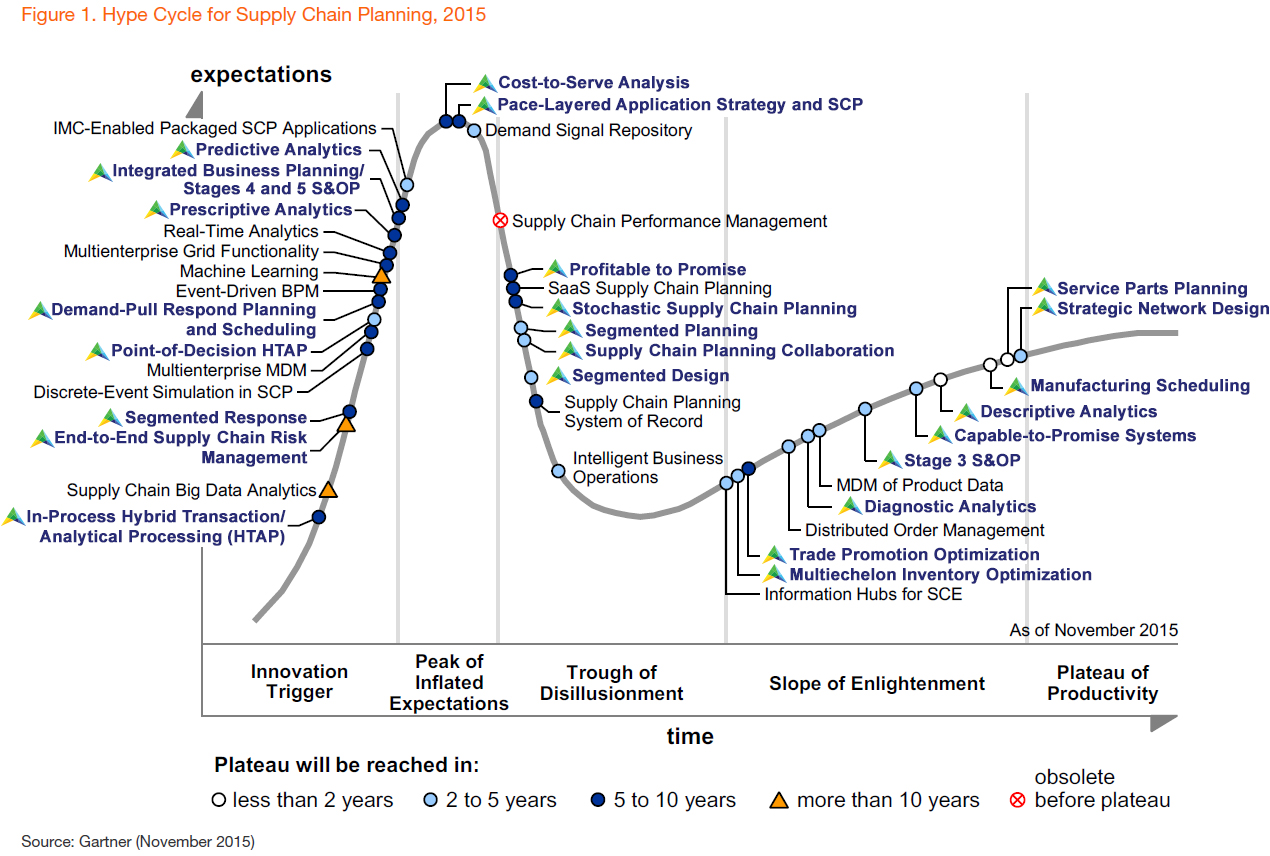

Gartner Blog Network

Sales And Operations Planning Anaplan Community

コメント

コメントを投稿